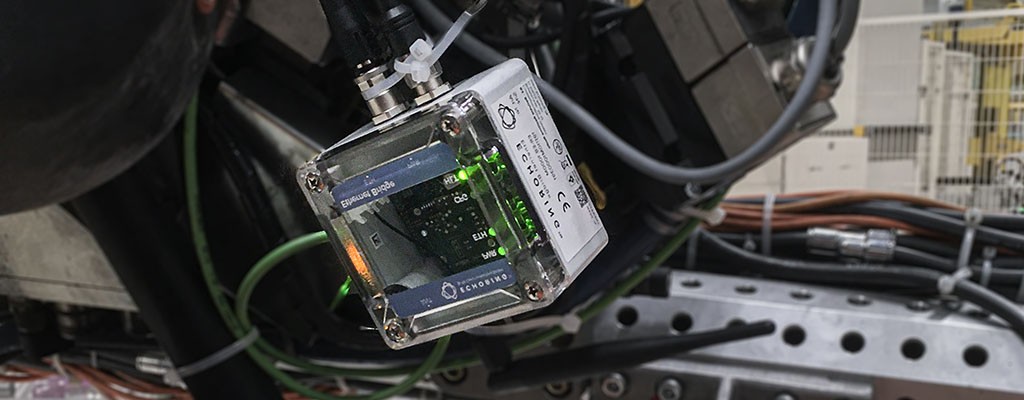

R3 – Reliable Realtime Radio develops high-performance wireless industrial solutions. R3’s EchoRing protocol combines the reliability of a cable connection with the flexibility of a wireless network, ensuring latencies of under five milliseconds. The protocol is designed for a wide range of industrial machine-to-machine applications, up to and including critical safety protocols such as emergency stops. EchoRing’s expanding list of users includes industry leaders such as Wienerberger, Götting KG, and Kuka.

If wired communication lines to industrial robots fail unexpectedly due to wear or carelessness on the shop floor, automated production can come to a halt in a matter of seconds. If this occurs, the new wireless “EchoRing Emergency Kit” can be used to quickly create fully functional, radio-based substitute connections, as the kit has successfully demonstrated over several months of use at the BMW Group Plant Leipzig.

When robots stop working due to a sudden failure of trailing cables or tool connections, the EchoRing Emergency Kit allows production to resume quickly. While EchoRing ensures the transmission of production data as a bypass solution, Engineers can promptly diagnose the cause of a cable failure. If Engineering can only fix the problem during the next scheduled maintenance or if more extensive repairs are required, the EchoRing emergency kit ensures the individual system’s continued operation for more extended periods.

BMW Group has been using the EchoRing Emergency Kit from R3 – Reliable Realtime Radio at its Leipzig production site for just over a year. Shortly after testing and evaluating a robot test cell, the system was introduced into productive operation at BMW’s Group Plant in Leipzig and fulfilled higher complex robot systems requirements.

The EchoRing Emergency Kit contains all the hardware components required to bridge defective cable routes via radio data transmission. These include “EchoRing Ethernet Bridges” together with the corresponding antennas and installation cables, device-specific adapter kits (e.g., for PROFINET communication), and unique accessories for mounting the EchoRing components on the individual robot. An optionally available tablet (“Health Monitor”) allows quick and optimal configuration of the EchoRing radio network. It enables the user to view information on the radio quality at any time or as required.

Technicians can customize the scope of the solution provided to meet the needs of each customer. The EchoRing Emergency Kit works with various robot systems (e.g., ABB, FANUC, KUKA).

Although the temporary bridging is primarily intended for emergencies, the radio links set up can also be converted into a permanent solution. EchoRing technology allows uRLLC-compliant data communication (ultra-reliable and low-latency communication) in the 5 GHz frequency band, making it a fully-fledged alternative to classic Ethernet or Industrial WLAN installations. Based on the Token Ring concept, EchoRing enables data radio connections with latency times of less than five milliseconds at transmission rates of 5 to 36 Mbit/s (depending on bandwidth and priority traffic).

More info : www.r3.group